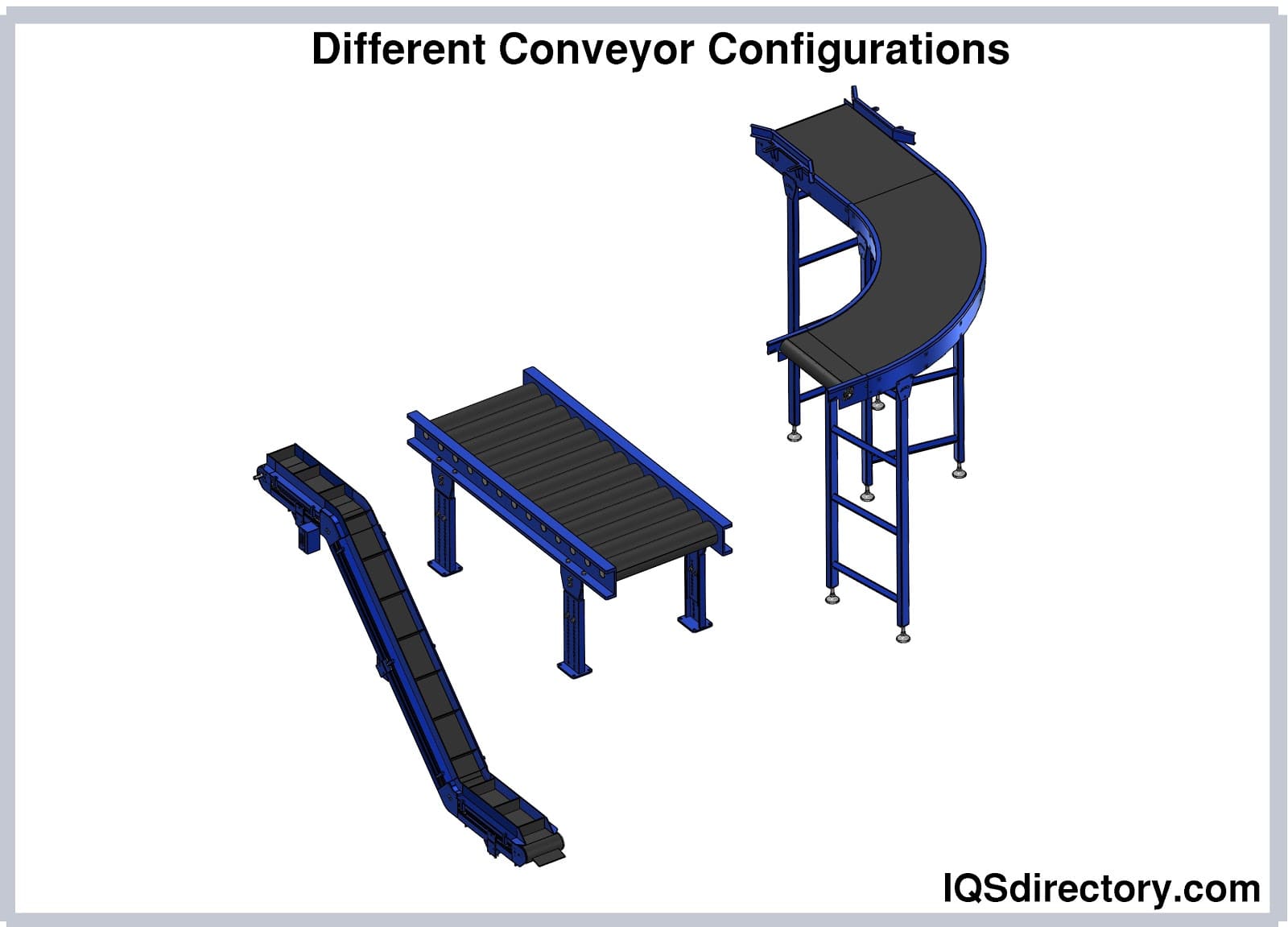

If a gravity roller conveyor is tilted or mounted on an angle, pieces of various sizes are moved by gravity. Workers must take care to prevent larger items from colliding with smaller ones. Shipping companies employ gravity roller conveyors to load and unload trucks. The three most prevalent types are overhead, belt, and roller, with overhead being the two-fold form.

Material Handling Requirements

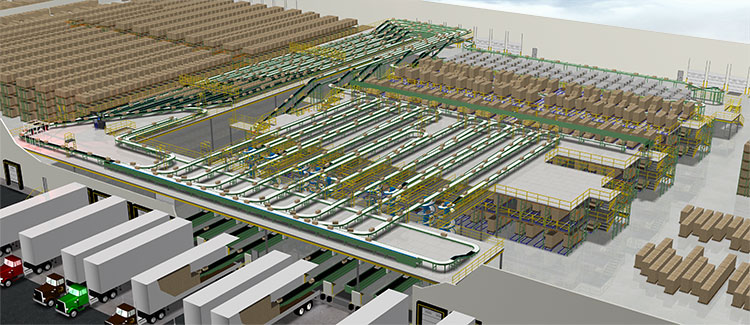

The goal of these systems is to enhance efficiency by reducing manual handling, therefore minimizing errors, and expediting processes. They achieve scalability by providing customization to handle various sizes and types of products, therefore making them adaptable to a variety of industry needs. Downtime refers to the duration during which the conveyor system is not operational, typically due to maintenance, repairs, or other issues. By tracking downtime and identifying the root causes, manufacturers can implement preventive maintenance measures and optimize the system’s reliability. Throughput measures the number of units or materials that pass through the conveyor system within a specific timeframe.

Transfer requirements

Motorized Roller ConveyorsConveyors use motors to power evenly spaced rollers. It is connected by a chain or belt and sometimes has a sensor that prevents pieces from getting packed together. Each of these components must be carefully selected and engineered to work together seamlessly.

Pallet Handling Conveyors

Having the forethought to equip the system with necessary safety features will prevent injuries and providing access to conveyor components will promote regular maintenance, further maximizing efficiency. Contact JHFOSTER for more assistance with conveyor system selection and design. This may be the conveyor you are most familiar with, because it is the most commonly used type. Belting for conveyors is typically a large loop made of rubber or pvc, which is powered by two or more rollers. This type of conveyor belt makes it suitable for transporting fragile or small objects, but that same rubber construction means it can have trouble with heavy objects, abrasive or corrosive materials.

In Europe, conveyor belts have been used in industrial production since the late nineteenth century. Conveyor belts usually have two or more pulleys, with a continuous loop of material rotating around them. For example, a slat conveyor, made from slats or plates instead of a belt, is designed for moving heavy materials.

Slippage occurs when the coefficient of friction between the material and belt surface is less than the tangent of the angle of incline. If the cargo is spheroidal, wet, or tends to fluidize, the material may not go up the incline at all. Material testing of the coefficient of friction between the belt and bulk material under all likely conditions is important for consistent and reliable transport uphill or downhill. In many parts of the world, a system may work fine in the dry season but operate at a much lower capacity during the rainy season due to the changes in the coefficient of friction between the belt and load.

What to look for in a hygienic conveyor design - Packaging Digest

What to look for in a hygienic conveyor design.

Posted: Thu, 30 Nov 2023 20:34:37 GMT [source]

This article will provide an overview of the types of conveyor belts available. We will also discuss their benefits to a business and how to maintain a high-quality conveyor belt over time. Electrical engineering expertise is crucial for powering the system and controlling the movement of materials. This includes the selection and integration of motors, wiring, and power supply systems. Additionally, electrical engineers work on developing the circuitry for sensors and actuators, which are essential for automating the conveyor’s operations. This type of conveyor is particularly useful in applications where the products have a flat bottom and need to be accumulated or sorted.

Conveyor Design Considerations for Maximum Efficiency

Find out how we designed, supplied and installed a set of four conveyors to provide a flexible solution for weighing potatoes during the production process. The various types of conveyor systems means they are flexible enough to be installed in most facilities, with options to suit all facility sizes, budgets and project goals. By staying abreast of these emerging trends and technologies, manufacturers can proactively adopt innovative solutions to maximize production output, stay competitive, and thrive in the dynamic manufacturing landscape.

The Benefits of Investing in a High-quality Conveyor Belt

We explore the key components that contribute to optimal design, including belt material, pulley design, and belt tracking mechanisms. By understanding these factors and implementing the right conveyor belt design, manufacturers can enhance productivity, minimize costs, and gain a competitive edge in their industry. In the food processing industry, conveyor belts must meet stringent hygiene and safety standards. Food-grade materials that are resistant to contamination, easy to clean, and capable of withstanding frequent washdowns are necessary. Conveyor belt design for the food processing industry should also consider factors such as gentle product handling, minimal product spillage, and efficient transfer between different processing stages.

They are a safe way to move objects of all weights and sizes, but the skilled labor it takes to maintain and repair it means you could lose significant productivity if it goes down. As a leading manufacturer of conveyor equipment, including conveyor idlers, rollers, pulleys, frames, and customized solutions, our company is committed to providing high-quality products at a low price. In this article, we will highlight the advantages and benefits of belt roller conveyors, one of the key products in our conveyor system. For the pharmaceutical industry, conveyor belt systems transport cardboard boxes or palates full of medical supplies before and after packaging and distribution. In manufacturing and mining, enormous amounts of material are transported through tunnels, along roads and up steep slopes on conveyor belts.

Pulleys guide and drive the belt, with the drive pulley providing the necessary force to move the belt and its load. Motors power the system, while idlers support the belt and help maintain its tension and alignment. The support structure holds all these components in place, providing stability and durability to the entire system.

The materials conveyed by a slat system are typically too large or heavy for traditional belt movement. The conveyor belt system design is a sophisticated process that involves meticulous planning and calculations to ensure the system’s functionality, efficiency, and safety. This process includes several critical design calculations, each serving a specific purpose in the overall design of the conveyor system. The conveyor belt, often made from materials like rubber, PVC, or fabric, is the heart of the system, carrying materials from one point to another.

From initial design and configuration to installation and meticulous troubleshooting, Jordan is adept at handling all aspects of conveyor system management. For any inquiries or assistance with conveyor system optimization, Jordan is available to share his wealth of knowledge and experience. Feel free to reach out at any time for professional guidance on all matters related to conveyor rollers, belts, and accessories.

The belt has a continuous attachment to the rotor through the fiction which exists between both surfaces. For the efficient movement of the belt, the idler and drive pulley should function in similar directions which means either both operate in clockwise or anticlockwise directions. In general, conveyor systems are included with a belt that is stretched over 2 or more pulleys. As the belt surrounds the pulleys, it forms a closed ring so that the pulleys will be continually rotated in the loop. One of these pulleys is termed a drive pulley which pulls the belt and moves the items between different locations.

It is crucial to select the appropriate conveyor type based on the specific requirements of the application to ensure optimal performance and efficiency. By streamlining the production process, conveyor belts help reduce labor costs. In a conveyor belt system, the aluminum profile consists of the frame, belt and any supports. Systems that use a belt are generally powered by a motor, though conveyor systems can also use gravity or manual force to function.

No comments:

Post a Comment